- Home

- Investment Casting

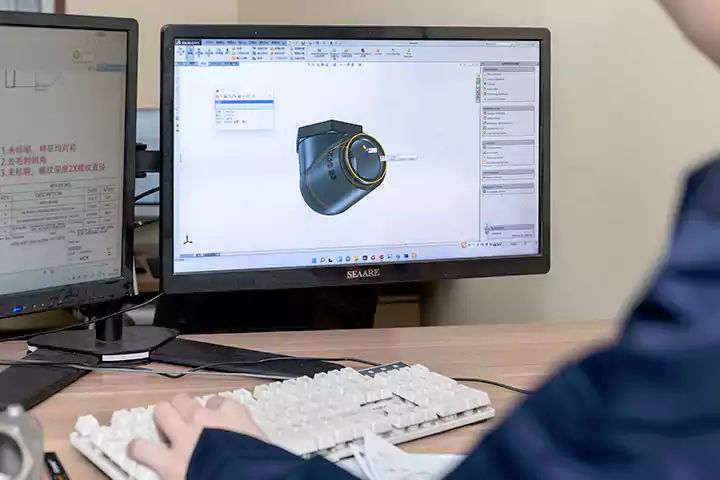

Precision Investment Casting Designed for You

TLP Casting is a professional and experienced investment casting manufacturer capable of making accurate metal parts that are uniquely designed for you through the use of stainless steel and carbon steel materials. Regardless of the complexity, budget constraint, or challenge that you have, your project will be achieved.

Why Choose TLP Casting

Low-Volume Production

Do you need just a few units of casted parts? With a Minimum Order Quantity (MOQ) of 500, you can get quality products at an affordable price.

Why Choose TLP

Endless Options

There is a wide variety of options to choose from. There are more than 50 casting alloys with various grades of metal that can be used for your project.

Quality Management

Our manufacturing process and raw materials comply strictly with the industry regulatory standards, including the ISO 9001, and Quality Management System.

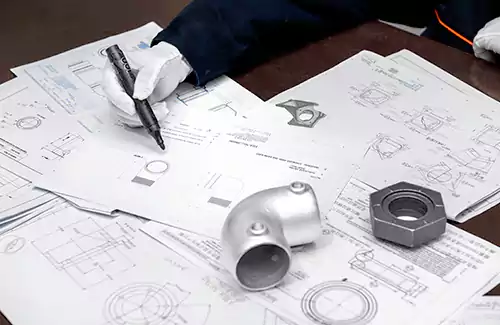

Investment Casting Process

Create the Pattern

Wax Injection & Assembly

Shell Making

Melting and Pouring

Complete the Process

Laboratory Inspection and Testing

Investment Casting Quality Control

Raw Materials Quality Control

We only source raw materials from certified suppliers with quality certificates to prove their authenticity. Immediately they arrive, they are inspected to confirm their reliability as any piece with an atom of irregularity is returned. Quality inspection records are kept for all raw materials.

Appearance Quality Control

All surface defects, including scales, cracks, air holes, shrinkage cavities, sand holes, etc are checked for. Our quality control experts conduct 100% inspection before shipping to clients. In doing this, they pick out castings with defects.

Chemical Composition Quality Control

We have Oxford spectrometers that can analyze the chemical components of metal alloys. Before the molten metal is poured into the mold, a portion of it is tested to ensure proper chemical composition.

Mechanical Properties Quality Inspection

To guarantee that the properties of the investment cast part are intact, various mechanical tests, such as hardness testing, tensile testing, and load testing are carried out. This is done to check for the performance and durability of the casted part.

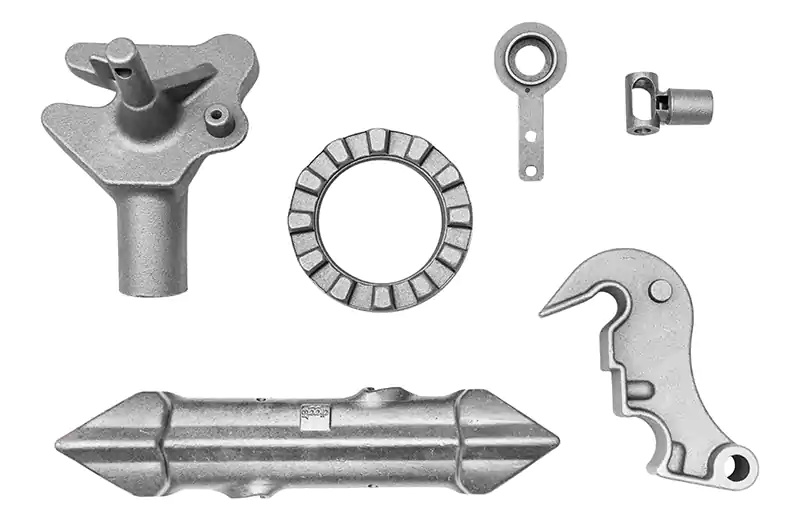

Investment Casting Service By Materials

Stainless Steel Investment Casting

Having high resistance to wear and corrosion, stainless steel is commonly used for demanding applications without the need to apply secondary coating or plating. Industries that usually use this material are oil & gas, defense, medical, etc.

Carbon Steel Investment Casting

It’s also known as plain steel as it contains mainly carbon, which contributes to its properties. It is very hard and strong, making it suitable for several heat applications. Some of its uses include ground-based military vehicles and roughneck equipment for oil & gas operations.

Available Investment Casting Finishes

Stainless Steel Shot Blast

Powder Coating / Painting

Electropolishing

Light Aluminium Oxide

Applications of Investment Casting

Having over 20 years of experience in providing investment casting services, TLP has garnered a wealth of knowledge to handle the most complex projects. No matter the requirements, be it the inclusion of intricate designs or short lead time, we are capable of meeting your needs. Our extensive capabilities extend to making casted parts for various applications, such as aerospace, oil & gas, and medical equipment & devices.

Request A Proposal

Make an appointment to visit factory online.Let our estimating and engineer team assess your project.Receive a proposal and free consultation.